3D printing enables agile production and helps bring creative ideas into reality

TT Gaskets’ investment in an industrial 3D printer has brought agility into the product development of different productional accessories.

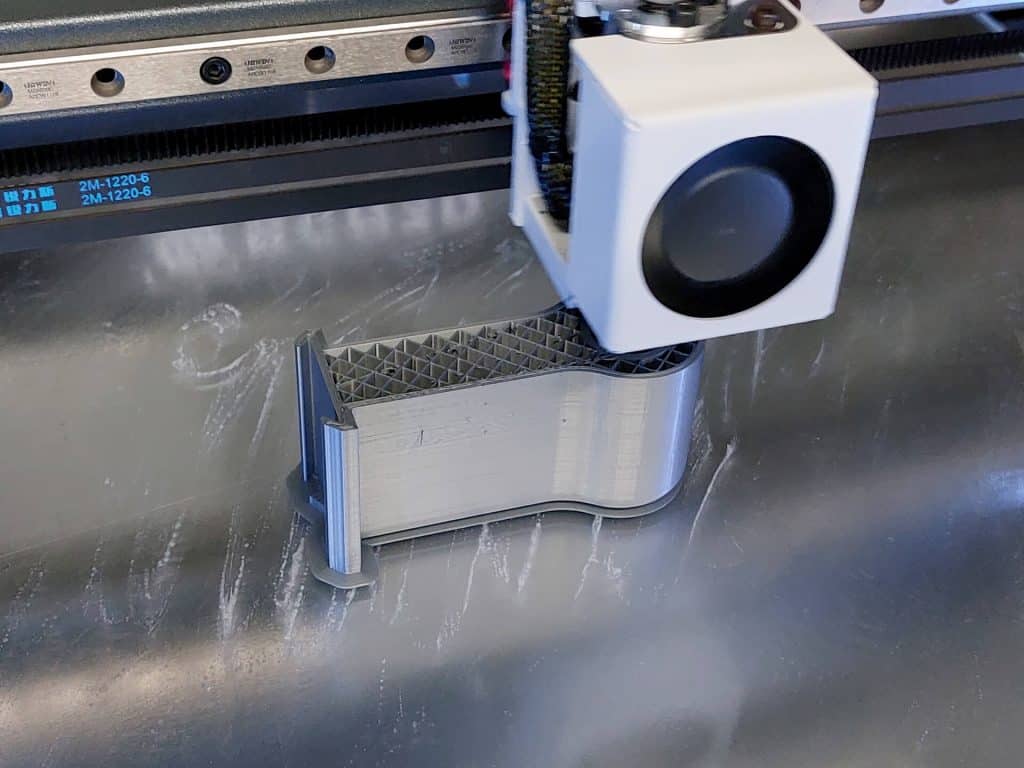

Getting accustomed to 3D printing started by practicing creating different shapes and measuring the dimensional accuracies of different plastic types.

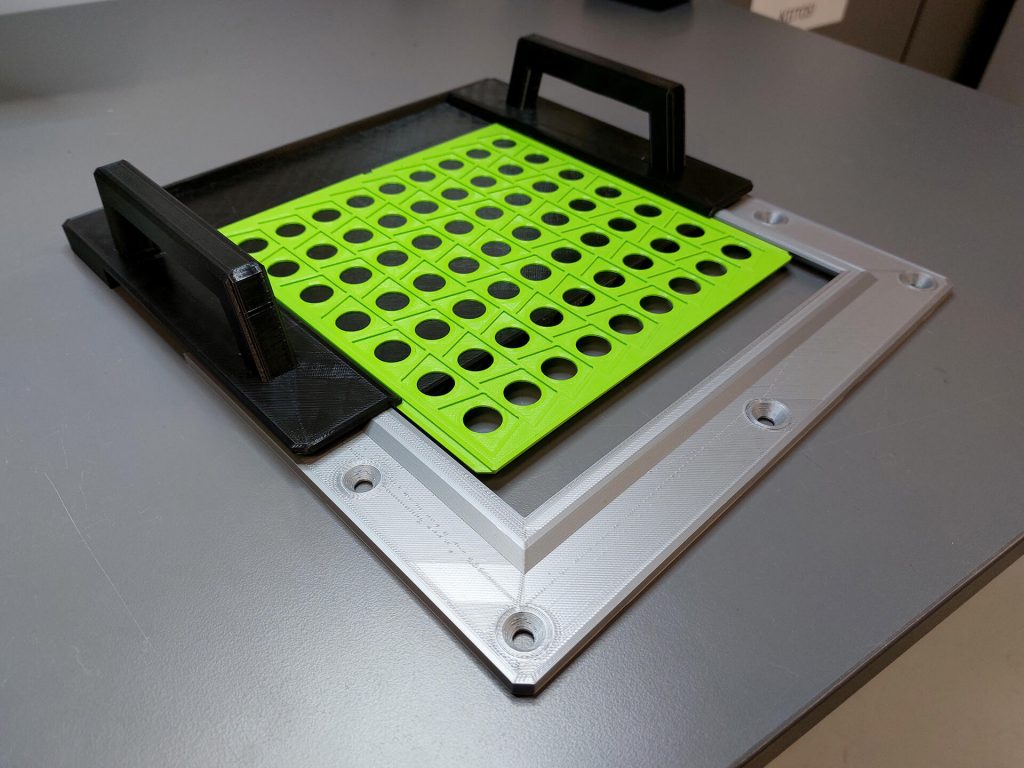

As we got comfortable with the technology, the printer was soon used in real-world applications. In-house product development quickly resulted in new innovations such as jigs and interchangeable trays that hasten laser marking, brackets for expanding our conveyor line, marking plates and other productional accessories.

These kind of creative solutions and applications make our production more agile thus benefiting both TT Gaskets and our customers. Many of the ideas for 3D printed objects have come from our production line. In some cases, an idea has been refined into a 3D printed product right away and implemented into our production the following day.

Great production benefits at a low cost

3D-printed objects have proven to be surprisingly fast to design and print – one object takes four to five hours on average to complete. Considering their low printing costs, the productional benefits are great – often these accessories hasten different operations significantly. Savings are indirectly generated at other departments as traditional methods and tools are not required to manufacture accessories and our production capacity can be fully allocated towards customer work.

We have also conducted internal experimentation on 3D printing different gasket components, and the results are promising. Time and further research will show if this technology can be utilized in our sealing products in the future. Meanwhile, we are also investigating the possibilities and benefits of 3D printing metals.