Gaskets With Metal Eyelets

A gasket with metal eyelet excels in its resistance to pressure and pressure surges. For this reason, it is a superb choice for sites where flowing medium is straining the basic gasket materials.

The metal eyelet boosts the strength and protection against temperature, chemicals, pressure shock and therefore is widely used in the process and petrochemical industry.

We provide the standardized gaskets with metal eyelets as well as the fully customized metal eyeleted gaskets to thoroughly meet your needs.

FAQ

Gaskets With Metal Eyelets

Example Use Cases

You can use gaskets with metal eyelets in many different applications. To give you a better idea, we’ve featured example use cases below from a Pulp Mill, a Power Plant, and Combustion Engines.

Power plant

Steam is a rather difficult media to seal as it is often combined together with extreme temperature and high pressure. The pressure shocks are often present whether you want them or not.

A Basic graphite gasket will maintain a leak-free environment if everything stays stable.

However, this is not the case very often, and therefore several power plants have decided to improve their basic graphite gaskets with an internal eyelet.

In practice that means a longer lifetime for the gasket, fewer leakages, and a safer working environment.

With a low-cost addition to a basic gasket, the gaskets with eyelets have a superior sealing performance.

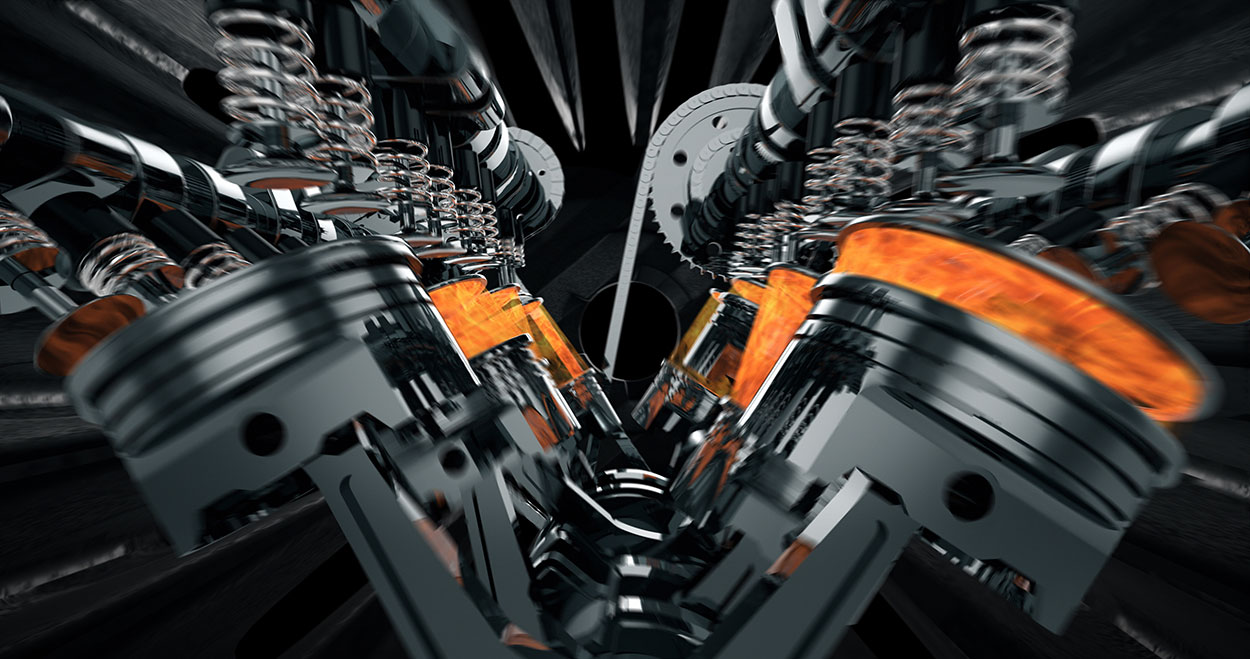

Combustion engines

There are a lot of applications in the combustion engines where a gasket with an eyelet makes all the difference in the world in terms of seal-ability.

Before, when now-banned-materials were used, it was not so difficult to achieve a required tightness class for combustion engines.

Today things are very different than those days, and we have materials that are better to our health. Also, at the requirements for the tightness have become more strict than before.

In combustion engines, small leakages are not accepted.

This means that us as a sealing professionals need to prove ourselves to our customers, time after time.

In many of these times, a gasket with an eyelet has been one of the key elements improving our customers’ life.

Whether you are sealing a turbo or an exhaust system, a gasket with an eyelet is a crucial key to success.

The materials are also getting better for higher temperatures.

In the early days our customers used zinc coated low carbon steel, today they might choose EN 1.4828 (AISI 309) or even special alloys such as Inconel 625 for an eyelet material.

Pulp Mill

TT Gaskets started providing graphite gaskets with inner eyelets for paper and pulp industry a long time ago.

This was a huge success story then, and even after two decades our customers are still fully aboard.

It all began for us when our competitors had supplied a low-quality gasket that were harmful within the industry. We were called to help. That was the moment when cheap low-quality gaskets were put aside.

Understandably because of those earlier times, the maintenance managers have become doubtful also of today’s gaskets having asbestos. We can assure you that all our gaskets are asbestos free.

TT Gaskets has been a tried and trusted partner for a long time to our clients within the paper and pulp industry.

Together we are building a new future with no room for leakages.

These days pulp and paper mills are huge users of inner eyelet graphite gaskets.

Now, graphite gaskets with inner eyelets are sealing steam, cooking processes, evaporating processes, hot oil applications, and much more.