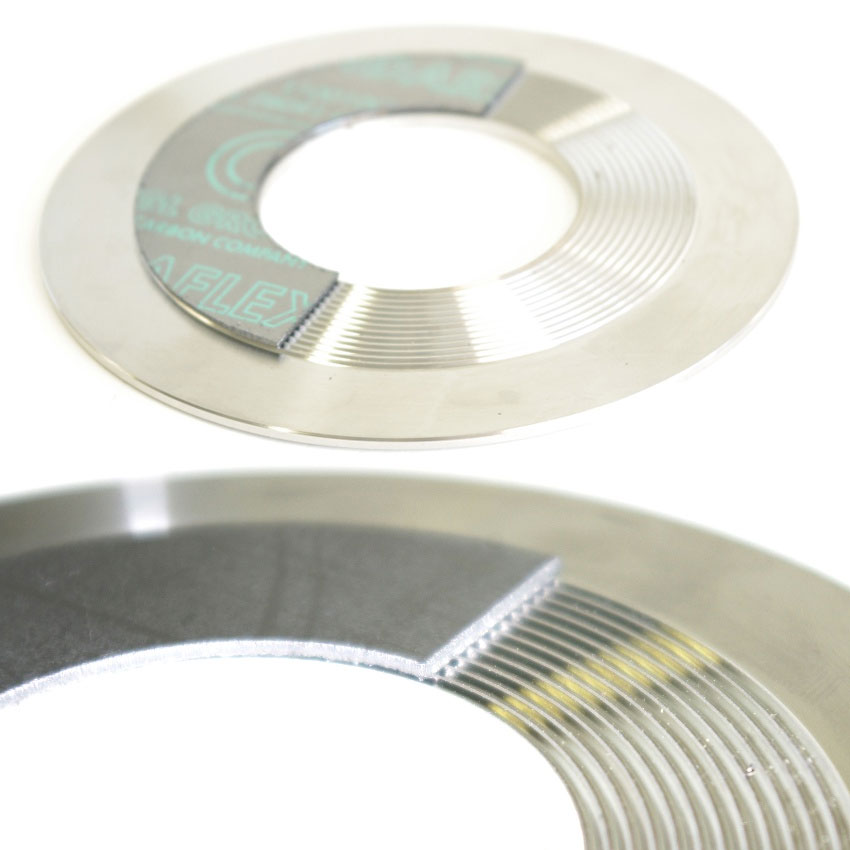

Camprofile Gaskets

A virtue of a camprofile gasket is its first-class wear endurance, temperature fluctuations and high-pressure shock resistance.

The camprofile gasket is outstanding in its excellent compressibility and recovery ability thus it is widely applicable in various industries.

The gasket frame is made from stainless steel and the structure achieves a great sealing in low surface pressure circumstances.

We manufacture the camprofile gasket according to the EN, ASME and GOST standards as well as fully customized based on your drawings or measurements.

FAQ

Camprofile Gaskets

Use Case Examples

You can use camprofile gaskets in many different applications. To give you a better idea, we’ve featured use case examples below from an Oil refinery and A Cruise Vessel.

Use Case: Oil Refinery

Oil refineries used to be full of double jacketed gaskets made of various alloys most commonly low carbon steel.

Have you ever thought about why on earth would someone try to seal metal against metal?

So did the maintenance managers in the refineries. Double jacketed gaskets were refurbished by adding graphite layers on both sides of a gasket.

That was one way to make a decent seal. So, the customer had a brand-new gasket but needed to repair it before using. For sure not time well spent.

Today majority of the double jacketed gaskets are replaced with a camprofile gasket. Especially as a heat exchanger gasket it has proven itself time after time.

You as our customer just need to peel the gasket of its wraps and it will be ready for tough action. The best prove of camprofile gaskets functionality is an old refinery and its old heat exchanger; you cannot find a splash beneath it!

Use Case: Cruise Vessel

With our own eyes we have seen an engine room in a huge cruise vessel where staff needed to wear respirators when taking care of their duties.

TT Gaskets was called in to solve the issue with leaking exhaust system. Our specialists went in, took pictures, measures, and application details, and took them back to the office.

Our design board saw this case as an interesting challenge.

After gathering all relevant data, the best possible solution was innovated; a very special camprofile gasket with a unique geometry following exactly mating parts of the sealing surfaces and flange geometry!

The surface area was reduced to meet the right gasket stress with the given bolt load. Should you ever need a camprofile even with a very special design and geometry, do not hesitate to contact our innovative sales staff.