Micaseal Suniflex – Premium heat resistance for demanding conditions

Micaseal Suniflex is mica-based gasket material designed for environments that require high heat resistance and versatile chemical resistance. It has plenty of use cases in power plants, combustion engines, exhaust systems and gas scrubbers.

Mica-based materials work especially well in places where graphite proves inadequate. Graphite-based materials start to slowly burn in temperatures over 450 °C and the burning intensifies the higher the temperature rises. Mica can withstand temperatures of over 900 °C.

The new material is available in three 316L steel reinforced thicknesses: 1.3 mm, 2 mm and 3 mm. Metal eyelets can be used to improve the material’s sealing qualities and leaking pressure even further.

The material has fulfilled our rigorous quality requirements and is available immediately. Micaseal Suniflex is well-suited for different gasket geometries, and we are happy to help you in designing sealing solutions for even the most demanding conditions.

Don’t hesitate to contact us and ask for more information!

Material Information

| Manufacturer | Planichem |

| Composition | Mica, tanged 316L steel insert |

| Applications | High Temperature Applications |

| Approvals | API Fire Safe |

| Colour | Beige |

| Thickness (mm) | 1,3; 2,0; 3,0 (two inserts in 3,0 mm) |

| Sheet dimensions (mm) | 1 000 x 1000, 1 500 x 1 500 |

| Density, (g/cm³) | 1,65–1,95 |

| Compressibility, DIN 3535-6 (%) | > 16 |

| Recovery, DIN 3535-6 (%) | > 3 |

| Tensile strength, ASTM F152 (MPa) | not defined |

| Stress resistance, DIN 52913 (MPa) | not defined |

| Specific leak rate, DIN 3535-6 (mg/s∙m) | < 0,1 |

| Thickness increase, ASTM F146 (%) | not defined |

| Compression modulus, DIN 28090-2 (%) | not defined |

| Creep relaxation, DIN 3535-6 (%) | < 12 |

| Peak temperature (°C/°F) | 1 000/1 832 |

| Continuous temperature (°C/°F) | 900/1 652 |

| Maximum pressure (bar/psi) | 60/870 |

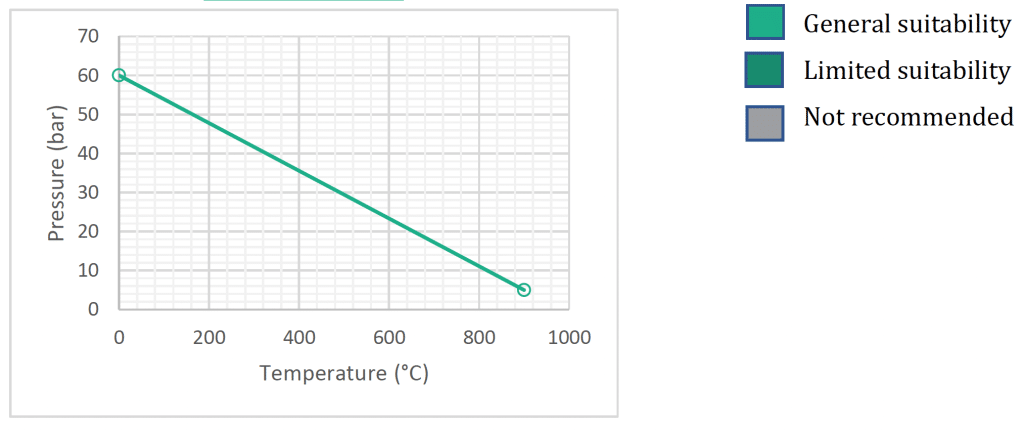

pT-diagram

Recommended Media

| Acetic acid | Dichlorobenzene | Methylene chloride | Sulphuric acid |

| Acetone | Dye liquor | Mineral oil | Tar |

| Acetylene | Ethyl acetate | Mobiltherm | Turpentine |

| Acrylic acid | Ethyl alcohol | Naphtalene | Toluene |

| Acrylonitrile | Ethylene glycol | Natural gas | Town gas |

| Air | Ethylene oxide | Nitric acid | Transformer oil |

| Alkaline lye | Ethyl ether | Nitrogen | Tributyl phosphate |

| Aluminium chloride | Ethylene | Oleum | Triethanolamine |

| Ammonia | Ethylene chloride | Oxygen | Urea |

| Amyl acetate | Fatty acids | Paraffin | Vegetable oil |

| Amyl alcohol | Ferric chloride | Pentachlorophenol | Vinyl acetate |

| Aniline | Formaldehyde | Perchloric acid | Vinyl chloride |

| Aviation fuel | Formic acid | Petroleum | Vinylidene chloride |

| Beer | Freons | Phenol | Water |

| Benzene | Gas oil | Phosgene | Whiskey |

| Benzoyl chloride | Gasoline | Phosphoric acid | White spirit |

| Biphenyl | Heating oil | Pthalic anhydride | Zylene |

| Blast furnace gas | Hydraulic oil (glycol) | Potassium hydroxide | |

| Bleach | Hydraulic oil (mineral) | Potassium hydroxide | |

| Boiler feed water | Hydrazine | Potassium nitrate | |

| Brine | Hydrocarbons | Potassium permanganate | |

| Calcium chlorate | Hydrochloric acid | Producer gas | |

| Capro-lactam | Hydrogen | Pyridine | |

| Carbolic acid | Hydrogen chloride | Sea water | |

| Carbon dioxide | Hydrogen peroxide | Silicone oil | |

| Carbon disulphide | Hydrogen sulfide | Soda ash | |

| Carbon monoxide | Isopropyl acetate | Sodium bi-carbonate | |

| Carbon tetrachloride | Isopropyl alcohol | Sodium carbonate | |

| Chile saltpetre | Kerosene | Sodium cyanide | |

| Chlorine | Lime | Sodium hydroxide | |

| Chlorinated hydrocarbons | Lubrication oil | Sodium hypochlorite | |

| Chloroacetid acid | Machine oil | Sodium nitrate | |

| Chloro benzene | Magnesium sulphate | Starch | |

| Chromic acid | Malic acid | Steam | |

| Copper sulfate | Methane | Steam condensate | |

| Creosote | Methyl acrylate | Styrene | |

| Cresol | Methyl alcohol | Sulphur | |

| Crude oil | Methyl isobutyl ketone | Sulphur dioxide | |

| Cyclohexanol | Methyl methacrylate | Sulphur trioxide |