Moulded Rubber Products & Metal-to-Rubber Bonded Gaskets

We offer a wide range of versatile and durable rubber components for use in many different industries for sealing, cushioning and insulation purposes.

Whether you need a customized product or a high-volume mass-produced product, our team of experts can help you find the right solution for your application. Our products are manufactured to meet the highest industry standards, ensuring quality and reliability.

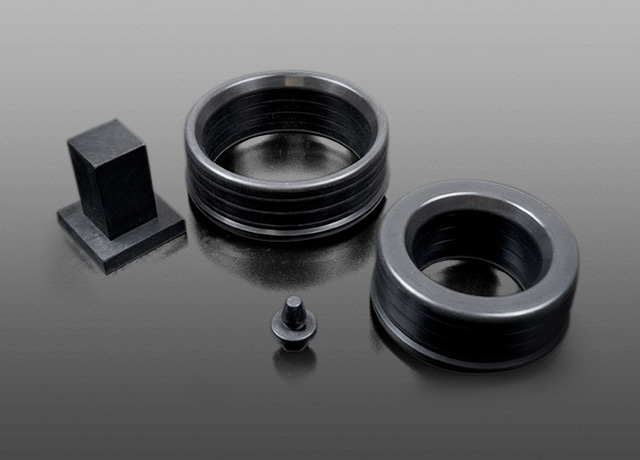

Moulded Rubber Products

Our moulded rubber products are the perfect solution for projects that require high performance and durability. They are customizable to meet stringent dimensional and material specifications, and are durable with excellent physical properties like tensile strength, elongation, compression set, and exhibit resistance to heat and oils/ lubricants. We have a wide range of materials available, everything from NBR, HNBR, NBR/PVC, EPDM, CR, FKM and silicone to many more special compounds based on the use application.

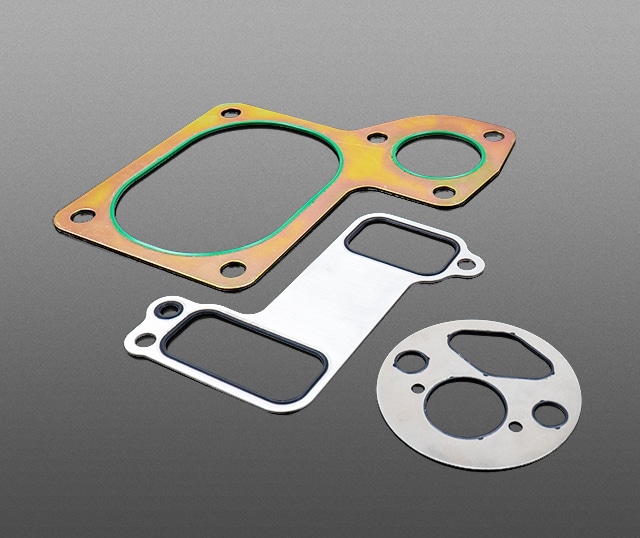

Metal-to-Rubber Bonded Gaskets

We offer a variety of high performance metal-to-rubber bonded gaskets that excel at great compression ratio at low surface pressure. Our products are optimal for high-pressure applications, they offer superior strength and durability, are resistant to high temperatures and corrosive substances and can be molded into complex shapes.

Manufactured with quality and precision

Our moulded rubber and rubber-to-metal products are manufactured typically according to the IATF 16949:2016 quality management system.

The raw materials we use comply with the requirements of the REACH regulation, and the products meet the restrictions set by the RoHS directive for the needs of electronics industry.

Our moulded rubber products can also be manufactured in material grades that meet the requirements for food industry (US FDA 21 CFR 177.2600 and EC 1935/2004).

Most of our products are customized for specific customers, and the tolerance ranges are agreed upon accordingly. The most common dimensional tolerances used are DIN ISO 3302-1 M3 and DIN ISO 3302-1 M2.