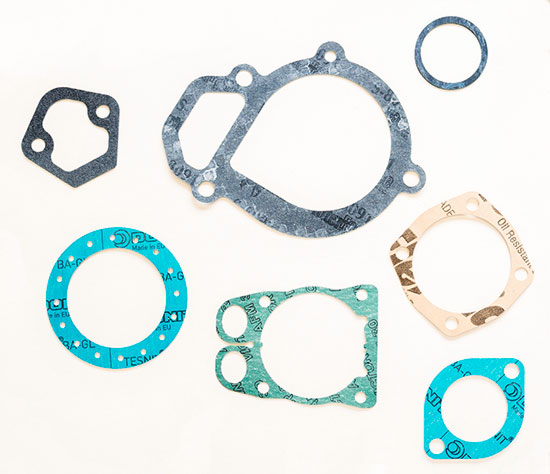

Gaskets

Our unique technical knowledge, decades of experience, and innovative thinking guarantee that we always provide the best possible solution to you.

We find the easiest and safest way for you to get the right gasket for the right application.

Each gasket is manufactured by the standards or fully custom-made to all your specific requirements, so that they provide exceptional durability even in the most demanding conditions.

Our gasket manufacturing process is effective, fast, and flexible, as we have most of the materials in stock in our warehouse.

FAQ

Gaskets

Use Case Examples

You can use gaskets in many different applications. To give you a better idea, we’ve featured use case examples below from Pulp Mill, Lighting Systems, and Combustion Engines.

Pulp mill

You can find gaskets everywhere you look. Most often you cannot see or hear them, but they exist in several places in our everyday life.

Often gaskets are in use in highly demanding environments such as a pulp mill. There are number of different applications such as power plants, evaporators, fibre lines and bleaching just as an example.

Those applications are sealed with different raw materials depending on the process temperature, internal pressure, and the media’s chemical resistance requirements.

These are the applications where you do not want to save money by choosing a cheap gasket, but the biggest savings can be made by choosing a right gasket for each application.

The overall cost in the world of gaskets is the only thing you should consider.

Combustion engine

Gaskets are widely used in the combustion engines. The current requirements in health and safety has set the bar high when sealing a combustion engine.

With our experience we can help our customers all over the world seal their engines in more cost efficient and enhanced way.

Whether you are wondering how your cylinder head, crankcase or oil pan should be sealed we are happy to prove our expertise. Our experience in sealing combustion engines has roots from 1940’s and the vast knowhow is still growing.

Lighting systems

Lighting system manufacturers worldwide are facing the same challenges and we have used to support them.

Most often the requirements for gaskets in lighting systems are not only the sealability but also isolating the light from escaping.

These gaskets are required to meet the requirements of certain fire classifications such as UL94 and sealability to meet certain IP-class. Please contact our sales staff to support.