Smarter sealing for a safer tomorrow – now in series

June 3, 2022

It’s no big secret that large series are not our cup of tea. We usually produce between 1 and 1,000 pieces and rarely series of over 10,000. By automatic pressing we can do up to 100,000 pieces, but those are usually small products. But as we are targeting larger global markets, we are facing more and more requests for large annual quantities.

Answering the demand with technology

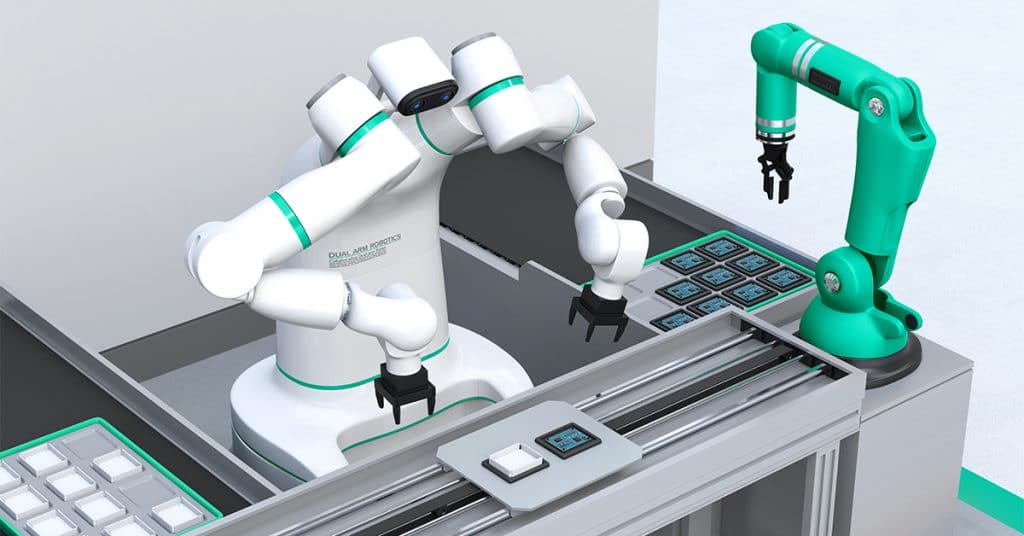

As per usual, we at TT Gaskets rarely say no to potential or existing customers, so we are already working to meet this demand. Last time I wrote about the automatic turning cell, and we have also made another investment in automated production. Before the end of this year, we should have a new traveling head die cutter that has cobots as coworkers. The new cutter replaces our old traveling head cutter that has well deserved its retirement.

Leaning the process

The new production cell is beneficial especially for cutting large quantities of metal reinforced materials. For large series our manual die cutting or even knife cutting can’t compete with the automated traveling head die cutter. The use of cobots streamlines the process substantially as they can pick the finished product from the conveyor belt and perform after treatments such as marking in the same cell. Before the incoming investment we had to pick the products manually and do after treatment separately.

Collaborative coworkers of the future

Such as in the case of the turning cell with robots, the die cutter cell will be the first time we utilize cobots for our production. To put it shortly, they are more versatile and easier to program than “hard” robots but of course have some weaknesses such as strength. We hope that we gain good experiences from them, and they could be used in other tasks in our production as well. The silly, repetitive tasks are unfortunately not going anywhere when products are manufactured, so any help from machines is welcome – from both the perspective of management and employees.

So, in case you need large batches of gaskets or other components, don’t be afraid to ask us for help. Soon we’ll provide Smarter sealing for a safer tomorrow also in series.